INTRODUCTION

Thermo welding, also known as exothermic bonding,

thermite welding, and thermit welding, is a type of welding that uses molten metal to permanently unite conductors.

To heat the metal, an exothermic reaction of a thermite composition is used, and no external source of heat or

current is required. The heat is generated by an

aluminothermic reaction between aluminium powder and metal oxide.

Exothermic welds are particularly helpful for connecting incompatible metals. The procedure has the benefit of requiring no external heat source and operates by using a chemical exothermic reaction of a thermite composition (weld powder) to heat the conductors to the point where a low resistance, mechanically sound molecular bond is created once cooled.

ADVANTAGES

- Thermo welding is a simple and fast process of joining similar or dissimilar metals.

- This process is cheap, as no costly power supply is required.

- This process can be used at the places where power supply is not available.

APPLICATION

- Very thick and heavy plates welding

- Joining rail roads, Pipes and Thick steel sections.

- Heavy castings and Gears repairing.

- Locomotive rails, Ship hulls etc.

- Welding cables made of copper.

EQUIPMENT

- Welding Powder

- Welding Mould

- Flint Gun

- Mould Sealer

- Corrosion Tape Strip

- Handle Clamp

- Igniter (Lighter)

- Mould Cleaning Scraper

- Mould Cleaning Brush

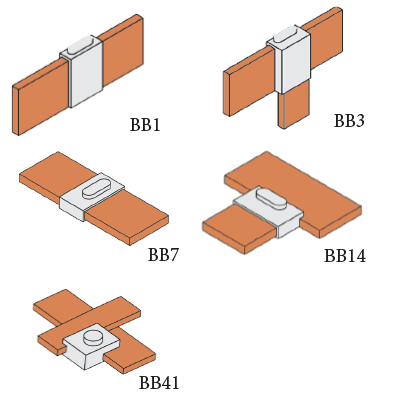

Bar to Bar

- BB1: Conductor size from 25×3 to 50x6mm

- BB3: Conductor size from 25×3 to 50x6mm

- BB7: Conductor size from 25×3 to 50x6mm

- BB14: Conductor size from 25×3 to 50x6mm

- BB41: Conductor size from 25×3 to 50x6mm (For both side)

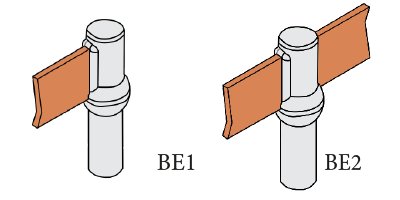

Bar to Earthing Rod

- BE1: Conductor size from 16 to 20mm and 25×3 to 50x5mm

- BE2: Conductor size from 16 to 20mm2 and 25×3 to 50x5mm

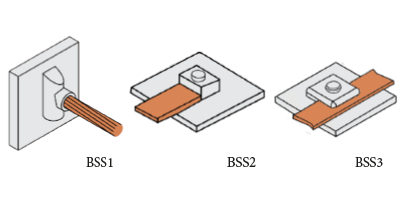

Bar to Steel Surface

- BSS1: Conductor size from 25×3 to 50x6mm

- BSS2: Conductor size from 25×3 to 50x5mm

- BSS3: Conductor size from 25×3 to 50x6mm

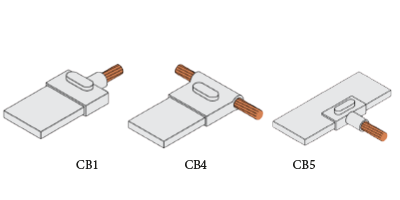

Cable to Bar

- CB1: Conductor size from 10 to 300mm2 and 25×3 to 50x6mm

- CB4: Conductor size from 10 to 300mm2 and 25×3 to 50x5mm

- CB5: Conductor size from 10 to 300mm2 and 25×3 to 50x6mm

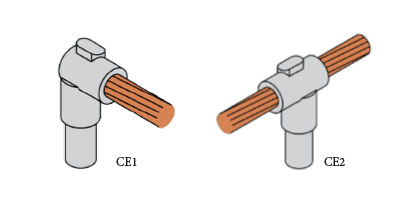

Cable to Earthing Rod

- CE1: Conductor size from 16 to 20mm and 16 to 300mm2

- CE2: Conductor size from 16 to 20mm and 8 to 300mm2

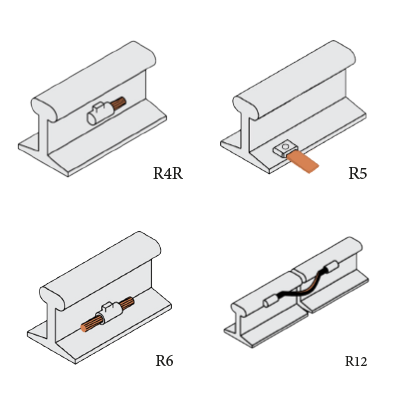

Cable to Railway

- R4R: Conductor size from 16 to 150

- R5: Conductor size from 16 to 150

- R6: Conductor size 25×3

- R12: Conductor size from 25 to 120

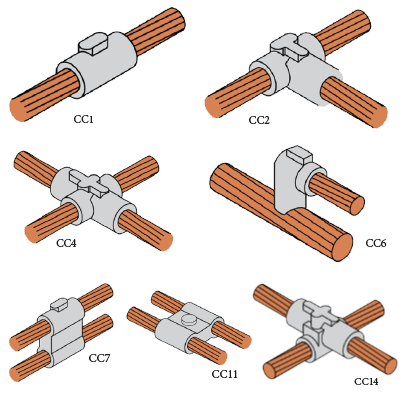

Cable to Cable

- CC1: Conductor size from 10 to 630 mm2

- CC2: Conductor size from 10 to 630 mm2 and 10 to 630mm2

- CC4: Conductor size from 10 to 240 mm2 and 10 to 240mm2

- CC6: Conductor size from 16 to 120 mm2 and 16 to 120mm2

- CC7: Conductor size from 10 to 300 mm2 and 10 to 300mm2

- CC11: Conductor size from 10 to 240 mm2 and 10 to 240mm2

- CC14: Conductor size from 10 to 120 mm2 and 10 to 120mm2

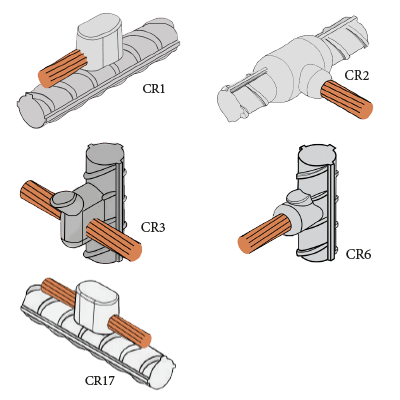

Cable to Reinforcement

- CR1: Conductor size from 20mm and 10 to 120mm2

- CR2: Conductor size from 16 to 30mm and 10 to 120mm2

- CR3: Conductor size from 10-40mm2 and 10 to 120mm2

- CR6: Conductor size from 10-40mm2 and 10 to 120mm2

- CR17: Conductor size from 20mm2 and 10 to 120mm2

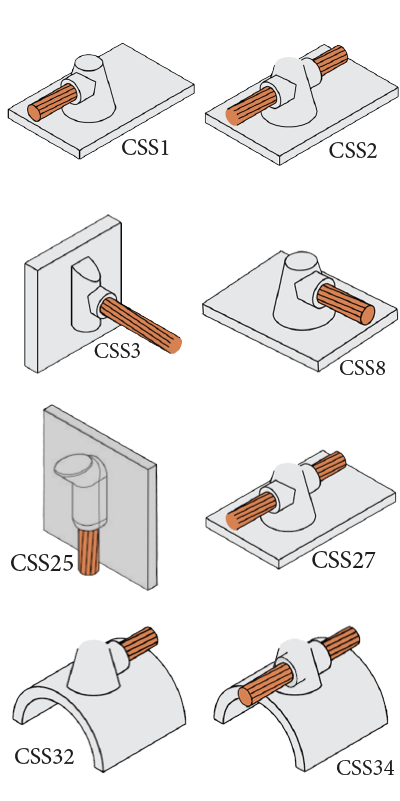

Cable to Steel Pipe or Surface

- CSS1: Conductor size from 10 to 300mm2

- CSS2: Conductor size from 10 to 300mm2

- CSS3: Conductor size from 10 to 300mm2

- CSS8: Conductor size from 10 to 300mm2

- CSS25: Conductor size from 10 to 300mm2

- CSS27: Conductor size from 10 to 300mm2

- CSS32: Conductor size from 4 to 70mm2 and <70 to >250mm

- CSS34: Conductor size from 4 to 50mm2 and <70 to >250mm