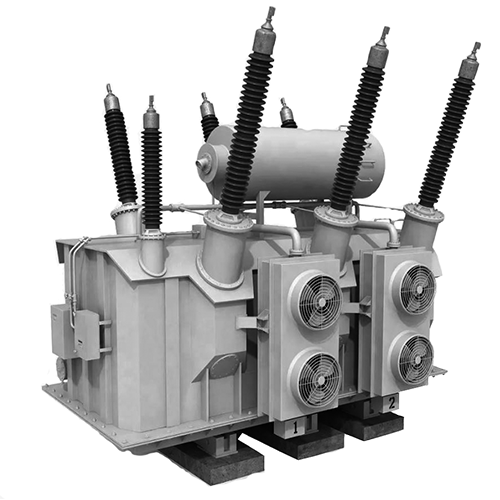

TECHNICAL DATA

Voltage Range: Up to 765kV

Power Range: Up to 1,250MVA

Core: Grain-oriented steel.

Windings: The windings are wound from aluminium or copper

upon the customer’s request.

Drying: The vapour phase drying & vacuum process is used for

each winding and active part in order to ensure stabilization and

drying.

Cooling:

• ONAN (Oil Natural and Air Natural Cooling)

• ONAF (Oil Natural and Air Forced Cooling)

• OFAF (Oil Forced and Air Forced Cooling)

• OFWF (Oil Forced and Water Forced Cooling)

Tank & Cover: The tank is made of steel plates that are

blasted and protected from corrosion of various environmental

conditions. (Heavy industrial, salty, tropical, etc.)

Product Standard: IEC 60076, DIN 42500-BS 50464

APPLICATION

- High Voltage Substations

- Medium Voltage Substations

- Hydro Power Plants

- Wind Parks

- Combined Cycle Power Plants

- Thermal Power Plants

- Solar Power Plants

ADVANTAGES

- Controlling and stabilizing the voltage transmission.

- It does not require any starting time.

- It is highly efficient with less capital investment and low

maintenance. - They provide isolation to the ground.

- There are no moving parts in Power Transformers.