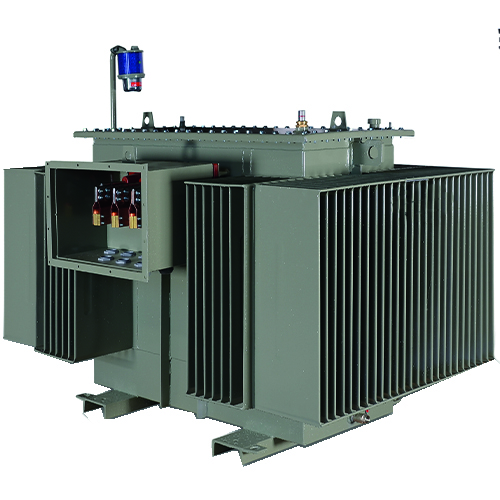

TECHNICAL DATA

Voltage Range: Up to 72,5kV

Power Range: Up to 20MVA

Core: Cold Rolled Grain-Oriented Silicon Steel

Windings: The windings may either be copper, aluminium upon the customer’s request.

Drying: The active parts of transformers are dried under a high vacuum in a furnace. The process of drying varies according to the transformer type, power, and voltage. Oil is filled under a high vacuum.

Tank: Tanks and top covers for transformers are made of mild steel. Cooling surfaces of distribution transformers are

constructed with corrugated walls and they also form the lateral surfaces of the tank. The bottom plate, sides, and frame are sealed by welding.

Product Standard: IEC 60354, DIN 42500-BS 50464

** It can be produced IP 23 Box type or with a fan according to customer demands.

APPLICATION

- Generation Step-up Units (GSU)

- Transmission Substations

- Distribution Substations

- Industrial Plants

- Chemicals & Petrochemicals

- Mining

- Desalination Plants

- Distribution Networks

- Private Properties

ADVANTAGES

- Due to the high pressure in control and protection of electrical transformer cabinets, no exposed live parts, safe and reliable. Excellent performance with energy-saving type transformers, energy-saving effect.

- Because the transformer cooling surface state in the outdoor natural cooling, cooling conditions, it is generally box-type transformer capacity of up to 1600kVA and below.

- May be needed as a terminal substation or ring.

- Inadequate modular box-type substation

- Due to high voltage switches in transformer cabinets, and therefore no obvious breakpoint and earthing switches. (Points, closing state is not intuitively obvious)

- Backup protection for a high-voltage fuse in the transformer cabinets, the relative difficulty replacement fuse blows.