INTRODUCTION

Explosion-proof junction box is a special type of electrical enclosure that is made to be installed in areas where there is a danger of explosion and/or fire of combustible dust. Depending on the type and design ex-proof junction boxes can be made of structural or stainless steel, aluminium alloy, zinc alloy.

Explosion-proof enclosures are designed for the arrangement of electrical equipment and its elements, as well as the protection of people from coming into contact with electrical parts integrated into enclosures of electrical equipment elements, and the protection of said parts from the environment and mechanical impacts.

ADVANTAGES

- Less power consumption-energy saving

- Long service life-maintenance-free

- Strong safety

- Conducive to environmental protection

APPLICATION

- Chemistry Plants

- Paint Plants

- Oil Storage Facility

- Energy Plant

- Harbour and Shipyard

- Oil Filling Plants

- Industrial Areas

- Fuel-Oil Station and Gasoline Storage

- Dry Cleaning Plants

- Spray Finishing Areas

- Aircraft Hangars

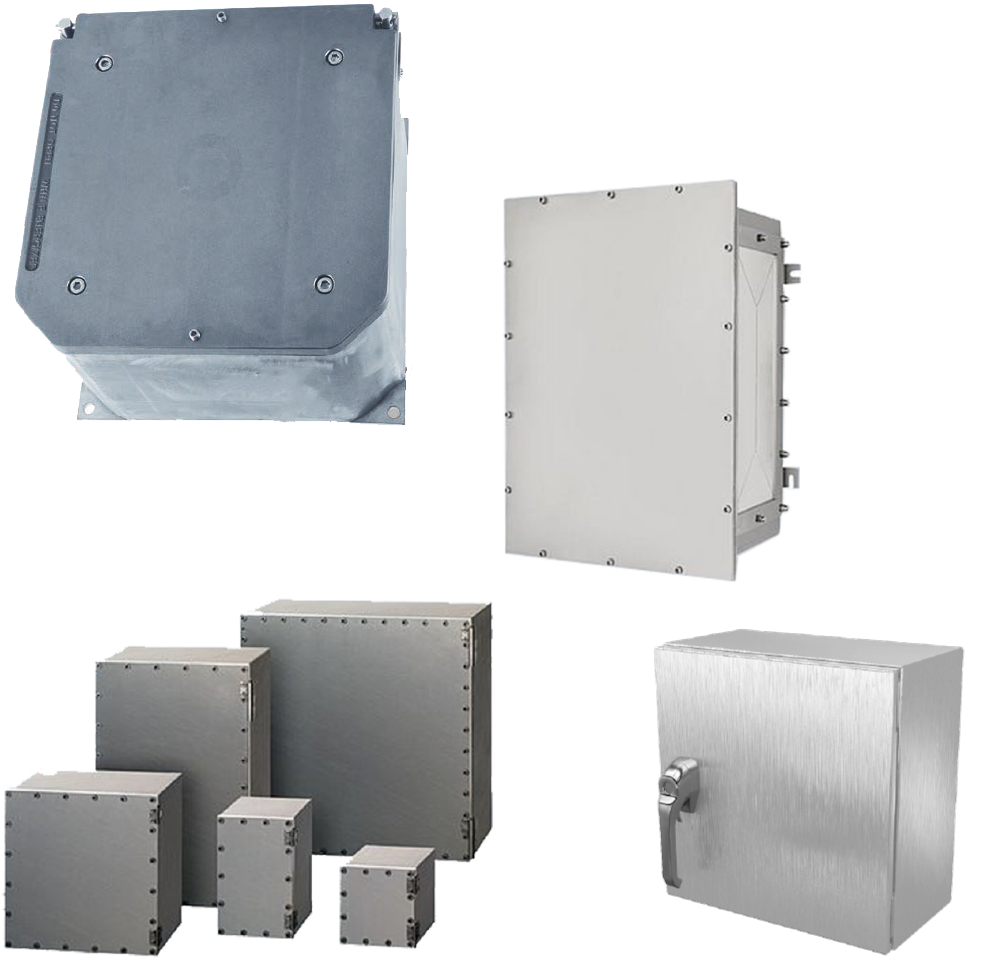

TYPES

- Ex-Proof Junction Box

- Ex-Proof Round Junction Box

- Ex-Proof Control, Monitoring and Signalling Devices

- Ex-Proof Aluminium Enclosure Systems

- Ex-Proof Polyester Enclosure Systems

- Ex-Proof Stainless steel Enclosure Systems

- Ex-Proof Hand-held Enclosure Systems

Ex-Proof Junction Box

Ex-proof junction boxes, also known as Electrical boxes, enclose wire connections. They help protect against short circuits, which can cause fires. Junction boxes are used in hazardous due to the presence of hydrogen or gases and vapours of equivalent hazard such as found in process industries, missile bases, and gas manufacturing plants.

Ex-Proof Round Junction Box

Ex-proof round junction boxes are made from aluminium alloy or stainless steel and are used to accommodate cables connected both with multi-pole terminal strips and modular terminals. These boxes cab be operating temperatures in the -40°C to +150°C range depending on their size, the type of gasket used and the terminals used.

Ex-Proof Control, Monitoring and Signalling Devices

Monitoring, controlling and signalling devices are installed as external accessories on ‘Ex d’ enclosures used in any industrial environment where an explosive atmosphere may be present, control devices can be used to close or open electrical or mechanical devices fitted inside the ‘Ex d’ enclosures while the signalling devices feature lights to indicate their operating status. The control and signalling device components are made from stainless steel to deliver unbeatable efficiency under any environmental conditions.

Ex-Proof Aluminium Enclosure

Ex-proof aluminium enclosures have high solvent resistance, a broad temperature resistance range and excellent corrosion resistance. The weight of aluminium is only about a quarter of that of steel. Ex-proof aluminium enclosures are also recyclable and light.

Ex-Proof Polyester Enclosure

Polyester enclosures are designed for use in harsh industrial situations because of their excellent temperature resistance, high impact strength, and durable structure. The enclosures are exceptionally sturdy and composed of glass-reinforced polyester. In harsh environments, they can be used in place of stainless steel enclosures. The low-cost polyester enclosing solution

employed is UV-resistant, self-extinguishing, and halogen-free.

Ex-Proof Stainless Steel Enclosure

Ex-proof stainless steel enclosures ensure correct service in the aggressive environments it is installed in. These boxes

successfully withstand harsh external factors such as water, dust, hard knocks, vibrations, corrosion, and extreme temperature fluctuations due to their high quality standard and use of select raw materials processed with cutting-edge technologies, ensuring a very long period of consistently reliable service.

Ex-Proof Hand-held Enclosure

Ex-proof hand-held enclosures are made of polyamide 12 and have an IP 65 degree of protection. They are utilized as

fundamental components for gas-detection equipment and other Ex-sector applications. In the case of the two smaller enclosure sizes, types with a closed top and a display opening are available. Includes a recess for Ex-certified membrane keypads for hand-held enclosure applications. These enclosures have a service temperature range of -20°C to +60°C.