TECHNICAL DATA

- Max. Operating Temperature: 90°C

- Rated Voltage: 300/500V

- Min. Bending Radius: 10x Cable Outer Diameter

- Production Standard: EN 50288-7

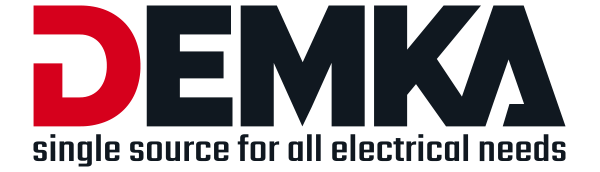

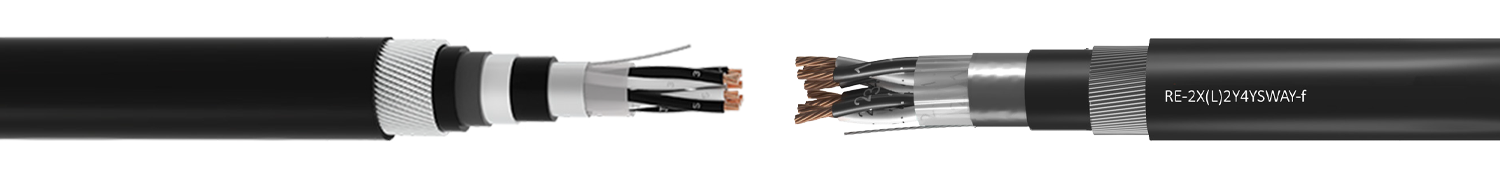

CONSTRUCTION

Conductor: Electrolytic, stranded, annealed plain copper Wires to IEC 60228 Class 2 (Class 1 or Class 5 and/or tinned on request)

Insulation: XLPE or PE compound

Binder Tape: Polyester foil on overall cable core formed by stranded Pairs

Collective Screen: Aluminium/polyester foil with a tinned copper drain wire in direct contact with the metallic side of the foil

Inner Sheath: PE compound

Chemical & Moisture Barrier (Multi Layer Sheath): AL Tape + HDPE + PA (Polyamide)

Armour: Round galvanized steel wires to EN 10257-1

Outer Sheath: Flame retardant PVC compound or HDPE Black for UV resistant and/or non-intrinsically safe cable

CODE of CABLE

- CU/XLPE/OSCR/AL/HDPE/PA/SWA/PVC; RE-2X(L)2Y4YSWAY-f

- CU/PE/OSCR/AL/HDPE/PA/SWA/PVC; RE-2Y(L)2Y4YSWAY-f

INTRODUCTION

These cables are used to connect instruments and control systems for analog or digital signal transmission in both indoor and outdoor applications. Because these cables are not meant to be used for power supply, they should not be connected directly to the mains electrical supply or other low impedance sources. Protection against aliphatic and aromatic hydrocarbons, engine oils, and other organic and inorganic chemicals is recommended. This multilayer barrier also provides exceptional corrosion and moisture resistance.

SECTION RANGE

- From 0.50mm2 up to 2.5mm2

CONDUCTOR QUANTITY

- From 2 pairs up to 30 pairs

COLOUR CODE of CABLE

- Insulation Colours code could be according to the

International Standards or customer’s request/demand.

* Other colours can be produced upon the customer

requests.